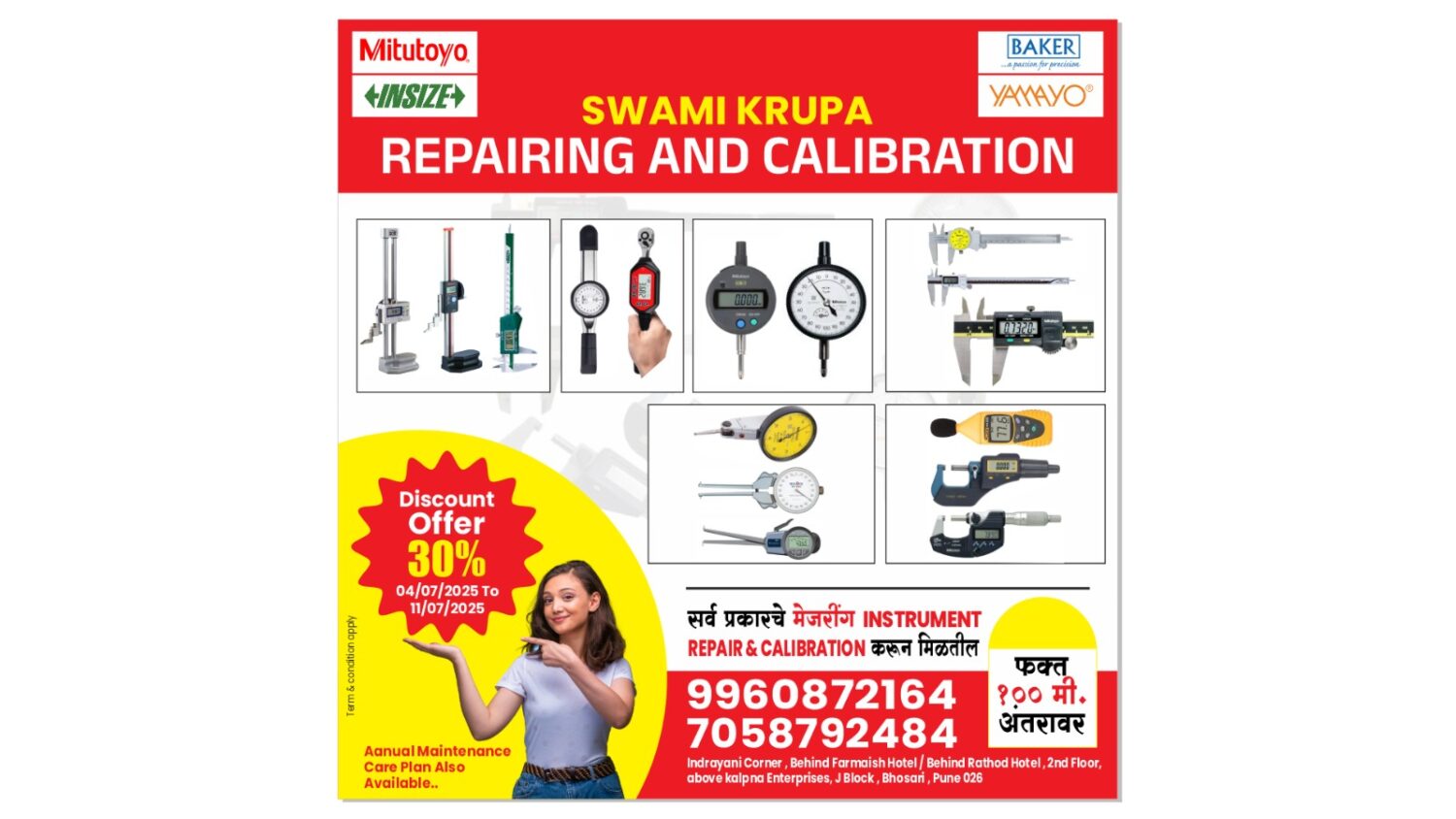

Measuring Instruments Repair And Calibration Bhosari

Swami Krupa Repairing & Calibration is a trusted service provider located in Bhosari, Pune, specializing in the repair measuring Instruments and NABL calibration of mechanical / Eletrical / Thermal , Pressure and digital measuring instruments. With years of hands-on experience, we cater to industries, workshops, and individual professionals who rely on precision tools for their work. Our services cover a wide range of instruments including Vernier Calipers, Digital Vernier Calipers, Plunger Dial Gauges, Lever Dial Gauges, Two-Pin Dial Gauges, Digital Height Gauges, DFT Meters, Ultrasonic Thickness Gauges, Multimeters, and Clamp Meters, Pressure Gauge, Vaccum Gauge , Torque wrenches Special Cheaking Instruments , Mitutoyo Instruments , Baker Insruments , Insize Instruents , Etc

We are committed to delivering accurate, reliable, and prompt solutions, ensuring that every instrument meets standard measurement accuracy. Our calibration process follows professional guidelines, helping clients maintain quality control and compliance. We also provide NABL-certified calibration services through trusted partners.

Located at J Block, Indrayani Corner, back side of Farmaish Hotel / Rathod Canteen Hotel,Above Kalpna Enterprises 2nd Floor , Bhosari , Pune 026 our facility is equipped to handle both small and bulk instrument servicing. With a customer-first approach, we aim to provide affordable pricing without compromising on quality.

For quick assistance, reach us via WhatsApp/ Call : 9960872164 And Call: 7058792484 . At Swami Krupa, precision is our promise, and your satisfaction is our priority.

Digital Vernier Caliper Repairing

Repair Calibration Services For Vernier Caliper

Mitutoyo Service Center Bhosari

Baker Instruments Service Center

Repairing Calibration Mechanical Measuring Instruments

Repair Digital Height Gauge Mitutoyo make

Digital Height Gauge repairing service

Coating Thickness Gauge Repairing services in Bhosari Pune

Repair Services Outside , Inside Micrometer

Repairing Services Rubber Hardness Tester

Our Services

Repair Digital / Dial Vernier Caliper Calibration

We specialize in repairing and calibration vernier calipers by correcting lapping errors on internal, external, and depth jaws. Our process includes dismantling, precision lapping, alignment, and calibration, ensuring smooth operation, accurate readings, and long-lasting performance for industrial and workshop measurement Need

Repair Digital Height Gauge calibration

We repair height gauges and calibration by cleaning the digital unit, checking the battery connector, IC, and display, correcting errors, and ensuring precise calibration. Our process restores accuracy, smooth operation, and reliable performance for consistent measurements in industrial and workshop environments.

Repair Plunger Dial Gauge Indicator calibration

We repair plunger dial Indicators gauges and calibration by checking plunger movement, bezel, O-ring, and glass visibility, inspecting gear alignment and accuracy, and correcting errors. The process ensures smooth operation, precise calibration, and reliable measurements for industrial and workshop applications.

Repair Lever Dial Gauges Calibration

We repair lever dial gauges and calibration by checking lever condition, bearing status, and alignment, ensuring clear glass visibility, and adjusting pinion alignment with the soft gear. The process includes error correction and precise calibration for smooth, accurate, and reliable measurement performance.

Repair Micrometer Outside Inside calibration

We repair micrometers by checking anvil parallelism, ratchet pressure, and lock system, ensuring free and smooth spindle movement. The process includes cleaning, lubrication, alignment, and calibration to restore measurement accuracy and reliable performance for industrial and workshop applications.

Repair Digital External / Internal Micrometer calibration

We repair digital micrometers and calibration by checking display visibility, battery connector, and battery cap locking, verifying ratchet pressure, and ensuring repeatability of readings. The process includes cleaning, alignment, and precise calibration to restore accurate and reliable performance for measurement tasks

Repair Pressure Gauge calibration

We repair and calibration of pressure gauges by checking pointer repeatability, inspecting for glycerine leakage, and correcting errors in the Bourdon tube pressure system. The process ensures accurate readings, smooth operation, and reliable performance for industrial and workshop measurement applications

Repair Double Column Digital Height Gauge calibration

We repair and calibration of double column digital height gauges by checking display visibility, battery connector, hard gear alignment, soft gear alignment, and soft spring status. The process includes cleaning column teeth, adjusting alignments, and ensuring precise calibration for smooth, accurate, and reliable measurement performance

Repair Two Pin Dial Gauges calibration / Internal Caliper

We repair and calibration of two-pin dial calipers by checking reading repeatability, gear movement, and leg movement, and inspecting the bezel locking system. The process ensures smooth operation, precise calibration, and accurate measurements for dependable performance in industrial and workshop applications

Repair Digital Groove Caliper Calibration

We repair and calibration of groove calipers by lapping external and internal jaws and aligning the copper wedge. This process ensures smooth movement, precise jaw alignment, and accurate measurements for reliable performance in industrial and workshop applications

Repair Torque Wrenches calibration

We repair and calibration of torque wrenches by checking handle movement, ratchet click timing, and pressure applied during readings. The process also includes testing spring tension to ensure accurate torque measurement and reliable, consistent performance

Repair Coating Thickness Gauge / DFT Meter calibration

We repair and calibration of coating thickness gauges by checking reading repeatability, probe sensor function, and foil thickness. The process includes calibrating master foils, inspecting battery connector, and restoring all settings to ensure accurate and reliable measurements

Repair Rubber Hardness Tester Shore A , Shore D , Shore C calibration

We repair rubber hardness testers by ensuring reading repeatability and checking pointer hardness. Calibration is done using master pieces and DCT parameters to guarantee accurate and consistent hardness measurements

Repair Digital Clamp Meter , Multimeter calibration

We repair clamp meters and multimeters by checking display accuracy, battery and connector status, probe and clamp functionality, and internal circuit integrity. The process includes calibration, error correction, and testing to ensure precise electrical measurements and reliable performance

Repair Master Spirit Level calibration

We repair master spirit levels by checking vial integrity, bubble visibility, and frame alignment. The process includes cleaning, re-leveling, vial replacement if needed, and precise calibration to ensure accurate leveling and reliable performance

Mitutoyo Baker insize Yamayo classic Repair Measuring Instrument service Center

Bhosari / Chakan / Pimpri Chinchwad / Sanaswadi / Ranjangaon / Talwade / Hinjewadi / Katraj / Shivne / Ahmednagar / Pune / Mumbai

© 2025 All Rights Reserved.Swami Krupa Repair & Calibration

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.